Heavy-Duty 60 to 100hp Low-Body Tractor Mulcher with hydraulic offset headstock suitable for vineyard, orchard and tree-crop prunings up to 70mm diameter and general grass cutting, road-side mulching and control of sapling re-growth.

Photograph for illustration purposes - standard specifications may not match those shown.

|

FEATURES OF THE FARMLINER TMU MULCHER |

CONSTRUCTION |

- Double skin body gives stiffness and strength to handle the mulching power and driveline.

- The mulcher side walls are protected and reinforced by heavy-duty skids.

- Lower protection bar for the belt cover reduces cover damage from branches and prunings.

- A parking stand to hold the machine level in storage.

|

3-POINT LINKAGE HITCH |

|

- Category 1 & 2 heavy-duty linkage headstock is mounted to a pair of lubricated sliding tubes.

- Slotted top link clevis provides for floating operation.

|

|

- Mulcher is hydraulically offset on the sliding tubes from central to right-hand side offset position, ideal for mulching under trees and vines.

|

TRANSMISSION |

|

- Fitted with the Italian made Comer T312 gearbox and side-drive.

- Gearbox input can be either 540 or 1000 PTO rpm by reversing the side-drive pulleys which are interchangeable. The mulcher is supplied standard configured for 540 PTO rpm.

- The oil bath gearbox has a breather and level plug for routine checks.

|

- The integrated free-wheel in the gearbox allows for safe mulcher wind-down when stopped without driving through the gear box and PTO drive shaft.

- The gearbox, driveline, body and rotor are rated to 100 hp.

|

ROTOR |

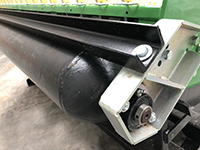

- The electronically balanced and 168mm diameter reinforced rotor is mounted on fully enclosed, self-aligning bearings with high radial load capacity ideal for the forces created by drive belts and the mulching operation.

|

|

- Internal bearings give a flat end plate for mulching up close to trees and obstacles.

|

|

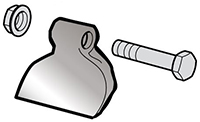

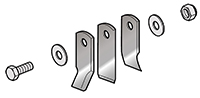

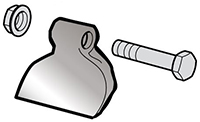

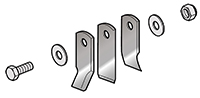

- Rotor is fitted standard with 1.8 kg RM10 hammers to effectively mulch prunings and woody vegetation.

- Optional Y-blades for predominately grass applications is available.

- The hammers spin through 420mm diameter circle at 2250rpm with a 49 metre/sec tip speed (176km/h) for superior mulching power.

|

- The hammer is forged, heat treated and hardened from high-grade steel.

- The hanging bolt is embedded into the hanging point for protection and to prevent spinning and unnecessary wear.

- The use of genuine blades, hammers and bolts are essential for safety, performance and protection of the mulcher.

|

MULCHING CHAMBER |

|

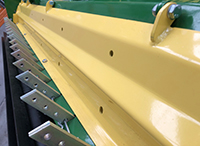

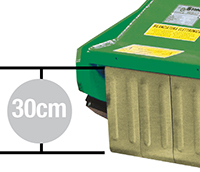

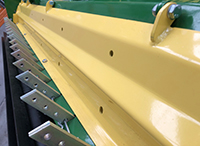

- Low body design with front and rear counter blades produces a finer mulch.

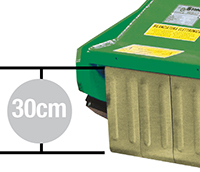

- 300mm high clearance intake better handles material flow into the mulcher without dragging and accumulating on the front edge.

|

|

- Counter blades resist the flow of larger material allowing hammers to produce a finer mulch.

|

|

- Rear rakes lift and retain prunings and branches until they are properly mulched.

- The combination of hammers, counter blades and rear rake tines working together to produce an excellent mulching environment for prunings.

|

|

- Openable rear door allows for easy access to inspect and replace hammers / blades.

|

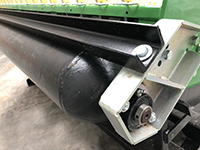

ROLLER |

|

- Skids provide primary protection of the body end plates and are not intended to be the means of height control.

- Mulcher height is set by the self-cleaning rear roller of 194mm diameter with scraper bar. Optional wheel kit is available.

|

APPLICATIONS |

- Clearing scrub

- Contractors

- Roadside maintenance

- Orchards (citrus, avocado’s, mango’s etc)

- Prunnings up to 70mm

|

OPTIONS |

|

- Y-blades in lieu of hammers.

- Rear wheel kit in lieu of rear roller.

- Automatically retracting inter-row mowing head for mulching along vines and orchard trees.

|

BROCHURE

Click this link to download a brochure.

Please note that Australian specifications may vary to those shown on the manufacturer's brochure and website.

|

Disclaimer: Specifications and features described on the website are subject to change without notice. All care has been taken to present accurate information, however, the company is not liable for unintended errors or omissions.

|